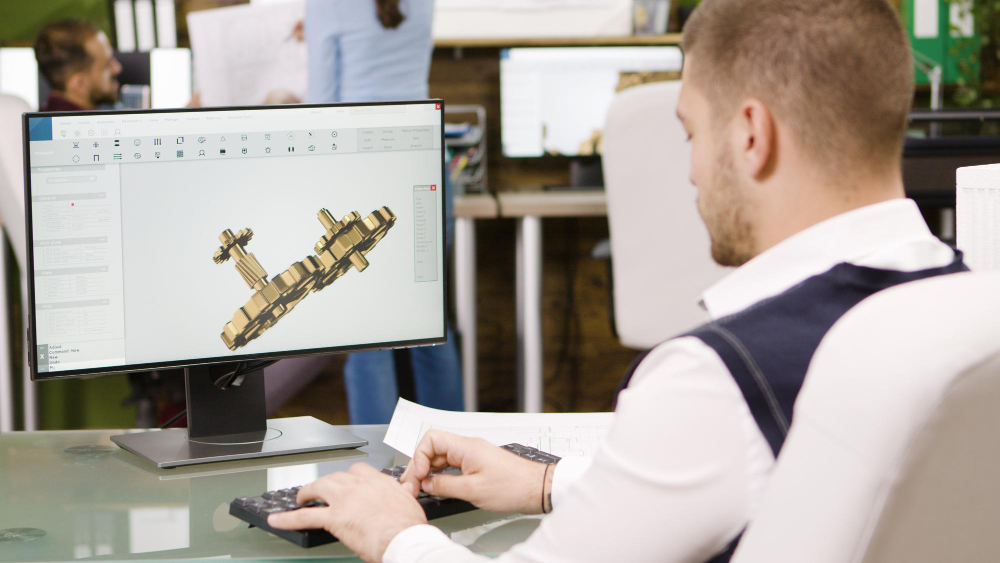

Industrial design plays a pivotal role in the creation of innovative and functional products. In an ever-evolving market, where consumers demand more, faster, and better products, industrial designers face the challenge of bringing new concepts to life efficiently. This is where rapid prototyping steps in as a game-changer in the design and manufacturing process. Rapid prototyping is a dynamic approach that has transformed the landscape of industrial design by enabling designers to create physical prototypes quickly and cost-effectively iterate on their ideas.

What is Rapid Prototyping?

Rapid prototyping is a set of techniques and processes used to create physical models or prototypes of a product idea. These prototypes allow designers, engineers, and stakeholders to visualize, test, and refine their concepts before investing in full-scale production. Rapid prototyping techniques are instrumental in accelerating the product development cycle, reducing costs, and improving the overall quality of the end product.

The Evolution of Rapid Prototyping

Rapid prototyping has come a long way since its inception. Initially, it was limited to basic 3D printing technologies that produced relatively simple and fragile prototypes. However, with advancements in materials, software, and hardware, the field has seen exponential growth.

- 3D Printing: The most prominent player in the rapid prototyping world is 3D printing. This technology has evolved from producing rough, proof-of-concept models to intricate, functional prototypes in a wide range of materials.

- Additive Manufacturing: Beyond traditional 3D printing, additive manufacturing processes like selective laser sintering (SLS) and stereolithography (SLA) have provided even more options for creating prototypes with different materials and degrees of precision.

- CNC Machining: Computer numerical control (CNC) machining has become more accessible and cost-effective, enabling the production of high-precision prototypes in various materials, including metals.

- Virtual Reality (VR) and Augmented Reality (AR): These technologies have expanded the possibilities for designing and interacting with prototypes in the digital realm before creating physical models.

The Benefits of Rapid Prototyping in Industrial Design

- Faster Product Development: Rapid prototyping accelerates the design process, reducing the time required to move from concept to prototype. This speed is a crucial advantage in a competitive market.

- Cost Reduction: By identifying and addressing design flaws early in the development process, rapid prototyping helps save costs associated with redesign and retooling.

- Improved Design Quality: Physical prototypes allow designers to evaluate the ergonomics, functionality, and aesthetics of a product, resulting in a more refined end product.

- Iterative Design: The ability to quickly create and modify prototypes facilitates an iterative design process, enabling designers to experiment with various concepts and refine their ideas efficiently.

- User Feedback: Prototypes can be tested with end-users, providing valuable feedback that guides the design and ensures that the final product meets the needs of the target audience.

- Customization: Rapid prototyping allows for the creation of highly customized and unique products, catering to niche markets and individual preferences.

Case Studies: Real-world Applications

- Aerospace Industry: In the aerospace industry, rapid prototyping has revolutionized the development of aircraft components. Companies like Boeing and Airbus use 3D printing to create complex parts with reduced weight and increased strength, ultimately leading to more fuel-efficient and environmentally friendly aircraft.

- Medical Devices: The healthcare sector benefits from rapid prototyping by producing customized prosthetics, implants, and medical equipment. This technology ensures a precise fit and improved patient outcomes.

- Automotive Industry: Major car manufacturers like BMW and Ford utilize rapid prototyping to design and test vehicle components quickly. This results in safer and more reliable automobiles with reduced development times.

- Consumer Electronics: In the fast-paced world of consumer electronics, companies like Apple and Samsung use rapid prototyping to develop cutting-edge products with streamlined designs and user-friendly interfaces.

Challenges and Considerations

While rapid prototyping has transformed industrial design, there are challenges and considerations to keep in mind:

- Material Limitations: The choice of materials for rapid prototyping may be limited compared to traditional manufacturing methods. Designers need to consider the trade-offs between material properties and design requirements.

- Cost: While rapid prototyping can save costs in the long run, the initial investment in equipment and materials can be a barrier for smaller companies and startups.

- Complexity: Highly complex designs can be challenging to prototype using certain rapid prototyping techniques. Designers may need to explore alternative methods or simplify their designs.

- Intellectual Property: The ease of prototyping can lead to concerns about protecting intellectual property. Companies must implement measures to secure their designs during the development process.

Rapid prototyping has become an indispensable tool in the field of industrial design. It empowers designers to bring their ideas to life quickly and efficiently, leading to better products, faster development cycles, and lower costs. The evolution of rapid prototyping technologies has broadened its applications, making it a key player in industries ranging from aerospace to healthcare. While challenges exist, the benefits of rapid prototyping are undeniable, and its impact on industrial design continues to grow, driving innovation and pushing the boundaries of what’s possible in product development. As technology advances further, we can expect rapid prototyping to play an even more significant role in shaping the future of design.

For more blogs related to design: https://www.dotsod.in/blog/

Follow DOT School of Design on Facebook, Instagram, LinkedIn, Medium and YouTube